Do you need a cable that can be used to power your newly acquired CCTV camera system? Would you like to install power and video runs using only one of your security cameras? The Rg59 Siamese Cable is the most popular cable for the job. Its application for power and video transmission are some of its advantages. It is also heavily secured from EMI (Electromagnetic Interference) and is mostly durable to take on long-term installation on long-distance runs. Look no further than in this guide; we will cover a cable meant for that and the best you can get for its value.

Chapter 1: Types of Cables for CCTV Cameras

Numerous components decide whether somebody will buy an IP camera framework or an HD DVR camera framework. However, the primary factor would be whether there is any current cabling setup that can be reused to keep away from the expense of running a new cable.

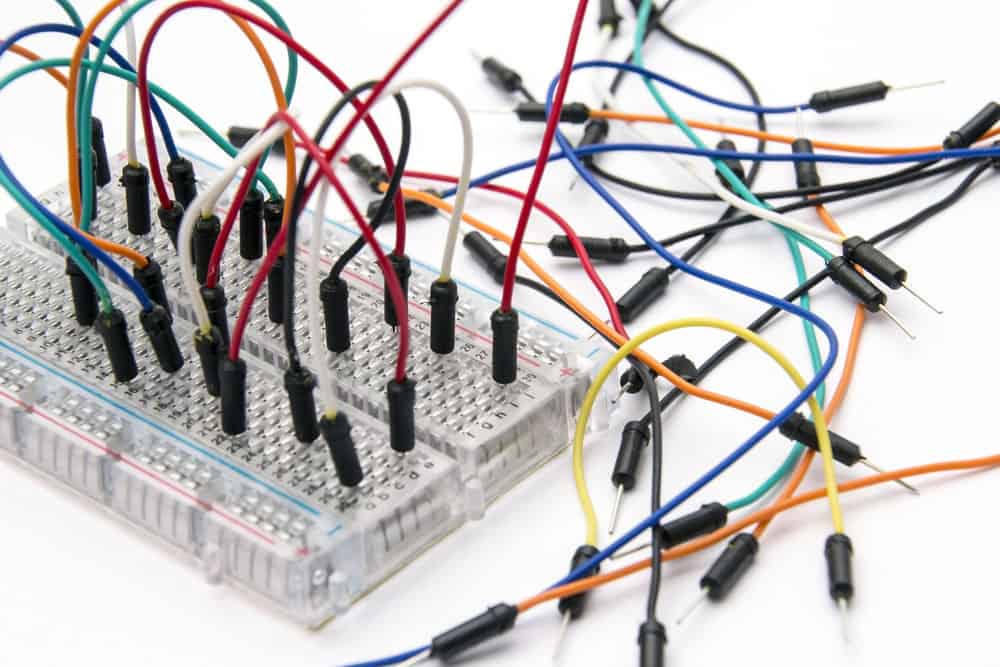

Siamese links are coaxial links onto which many intensity wires join. These power wires might be divided from the coaxial cable if the power source is distant from the account gadget.

Siamese Coax Cable

This is a “two-wire” solution coupled in one cable that permits pure power and video transmission for BNC cameras. It comprises two distinct cables connected in one cable coat. Attached is a video conductor that sends the video signal from the camera’s BNC connector. Moreover, a power wire transmits power to the camera from a closed power supply to the DVR recorder.

There are a few distinct grades of siamese cabling accessible for various video signals. These are of two main types:

- Pre-made siamese cable: This comes pre-assembled with differing lengths and end connectors. Pre-made CCTV cables accompany every one of the connectors pre-ended on the wires, so the installer needs to plug them in and turn on the cameras. They usually are offered in numerous lengths to help different lengths necessities. So it is imperative to gauge the distance from the surveillance cameras to the DVR (Digital Video Recorder), so you can pick the privileged premade links for your needs. These cables have developed in prominence and are perfect for do-it-yourself entrepreneurs looking for a quick and straightforward surveillance camera installation.

- Siamese Coax Cable: This comes from a spool or roll of higher quality. It has no pre-connected connectors, and the user needs to place the ends on them and cut them to any length.

Chapter 2: What is RG59 Siamese Cable?

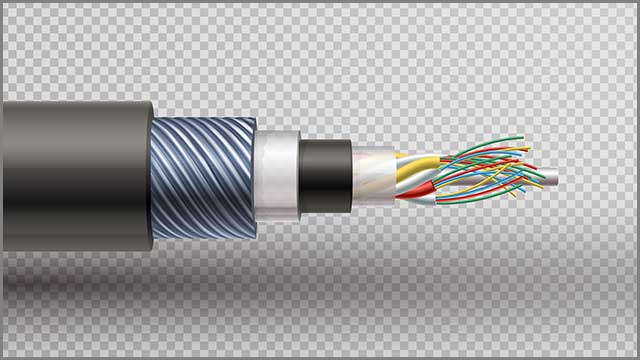

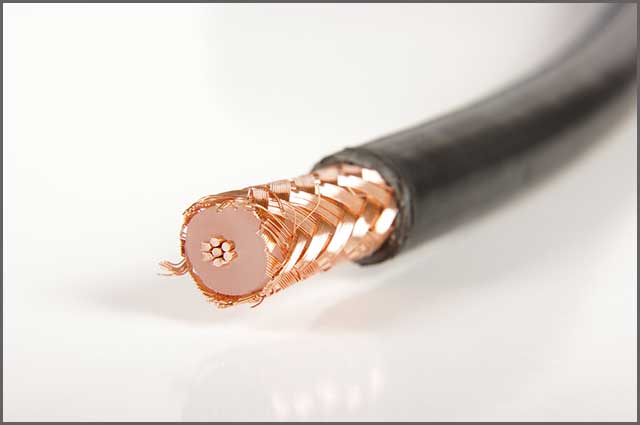

The RG59 Siamese Cable is a cable that allows installers to use a single cable to run both power and video to security cameras. It is heavily shielded; contains an RG59 COAX cable meant for video and 18 gauge power cable paired in one jacket.

The RG59 has an active copper center, 95% copper twisted protecting, and 75-ohm impedance. It is the best COAX cable to use when installing HD CCTV and CCTV. The18-measuree pair is used to runyour cameras’e AC or DC capacits.

RG59 Siamese Cable Pros:

Adaptability: These can be utilized to transmit both power and video simultaneously. In this way, they return exceptionally high an incentive for cash and are consequently extremely excellent buys.

Information Integrity: The functions of these cables permit the transmission of intensity with no undue obstruction with the transfer of video. This enormously improves the unwavering quality of information.

Rearranged Operations: The move toward setting up a video reconnaissance framework is significantly improved because both power and information are transmitted in a similar cable.

Versatility: The cables might be utilized nearby a few different hardware gadgets and cables, for example, shut circuit TV (CCTV), reconnaissance cameras, wired security framework, and RG59 coaxial cable.

RG59 Siamese Cable Cons:

Mind-boggling: They are progressively convoluted to deal with, introduce, and work when contrasted with other video security links.

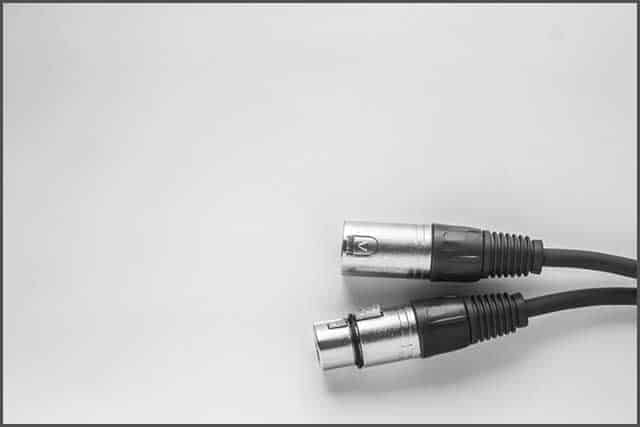

Chapter 3: RG59 Siamese Cable Connectors

Premade cables are cut to exact lengths, such as 50 feet or 100 feet, and connectors already exist. You just run the wire and attach it to the wall. However, you will buy two power pigtails and BNC connectors for every camera you tip and associate with your camera’s power and video connector. The following are the types of connectors for CCTV cables

1. Compression Style CCTV Connectors

Pressure style CCTV connectors are the exceptional connector of decision. These function well when you need a weatherproof seal. These connectors give an end and give long periods of issue-free administration. Since CCTV connectors cause the fundamental issues with lessening CCTV, it is best to ensure the first run-through is accurate. After that, check each run a connector has been introduced to ensure you are getting a great signal.

2 Plain Style CCTV Connectors

The use of connectors while installing untested cables can cause problems. These are exceptionally normal when introduced accurately, give long stretches of administration. The best problem with these connectors is that the installer gets some protective lines that come into contact with the inside stick, which causes the image to bend. This is because it is continuously harder to investigate a cable run after the installation as it causes considerably more work. Set aside the effort to add them effectively.

3. Other CCTV Connectors

These comprise elbows and twists, converters T’s, and connectors on CCTV connectors.

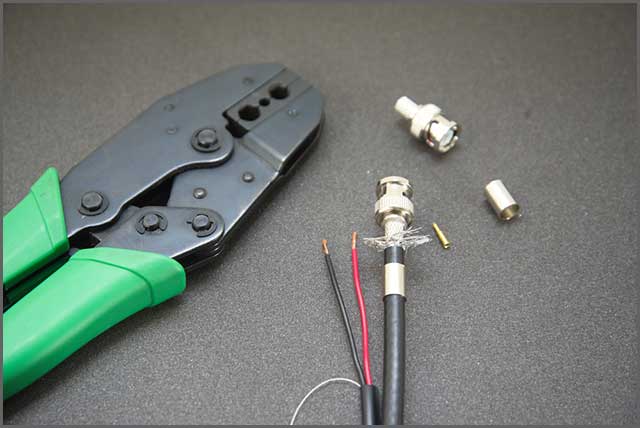

Chapter 4: How to attach these BNC Connectors

To do this, we would need the following:

- Rg59 Siamese cable connector ( industry-standard link utilized in CCTV camera installments).

- Compressor type F connector. This is an F to BNC male connector.

- Tl33 urge pressure apparatus.

- Tl22 cable stripper

- A standard wire shaper.

The initial step is to utilize our cable stripper to strip the persuade link appropriately.

Spot the Rg59 in the Tl22 cable stripper making around an inch stand out way past the apparatus. After that, turn the cable stripper around the cable five to ten times until you never again hear the device cutting.

The Tl22 makes two unique cuts in the cable. The second cut evacuates the external layer of the plastic coat. A more deep cut is made to the cable to strip all layers to leave just the core.

You need to ensure the more profound sharp edge did not cut into the center, which will weaken it. You likewise need to ensure that no part of the copper meshed cable touches the core.

It would help if you made sure that most meshed copper is left set up and not cut. After the cable has been stripped appropriately, strip back the braided copper shield.

This is significant. Try not to cut or expel the copper meshing. It is essential to ground the cable adequately. Recheck to affirm no shielding cable touches the coax of the cord.

Next, put the compression F connector on the wire. You should make sure the connector is set right on the cable, making the white separator come marginally via an opening in the connector.

Once in a while, it takes a touch of contorting to ensure the connector is seeded right. Here, the insulator becomes visible.

Trim the uncovered core to be equal to the end of the connector. After that, get the Tl33 compression device.

Place connector on it, ensuring cable core enters the gap on the compression instrument. After that, crush the tool. Then, the F connector becomes solidly joined to the Rg59 cable. Lastly, screw the BNC connector to the F connector.

This is an exceptionally safe approach for a BNC connector attached to an Rg59 coax cable and presumably the most loved strategy among most expert installers.

Chapter 5: RG59 Siamese Cable Length for Your Setup

How to manage wire lengths?

- Utilize a stripping apparatus to take protection from the coax portion of the cable. You can arrange a decent quality stripping apparatus here. Altogether, for the connector to go on smoothly, you will need around 3/4″ of the inside channel appearing and about a similar measure of the copper wire mesh appearing.

- Ensure that none of the strands of copper wire twist contacts the center conveyor wire when you wind on the BNC connector. On the off chance that they unintentionally touch, this won’t harm the camera yet can bring about a dark (shorted out) picture from the camera.

- Bend on the BNC Connector onto the wire until it is cozy. You will rehash Steps 1 – 3 for the DVR part of the arrangement link just as the camera end.

- Slice the wire on the camera power supply around 6 to 12 crawls from the camera connector. Strip back the wire (on the two sections) 1/2 inch or so to uncover the white (positive) and dark (ground) wires.

- Utilizing wire nuts, associate the power supply’s white wire to the red wire of the RG59 2 channel and the dark (ground) wire of the power supply to the dark wire of the two conduits.

Chapter 6: Customized rg59 Siamese Cable Assemblies

Wiringo can create your customized RG59 Siamese cables for households and industries. You can get all of your special cable assembly requirements.

Why do you need a custom CCTV cable?

We use these CCTV cables in our homes, workplaces, and offices for several video and audio components. CCTV cables are limited to individual use, but commercial sectors like telecommunication and the internet industry also use these cables for different purposes. If you have special needs and want a customized CCTV cable, we can engineer the perfect customized CCTV cable for your setup.

We provide customized cable connectors, connecting cores, harnesses, cable assemblies, and shielding for home and commercial use.

Tips for choosing the perfect RG59 Siamese Cable

When choosing the kind of cable to use for your undertaking. You ought to utilize the most astounding quality cable accessible with the goal that it will be sufficiently able to keep going for quite a while. For example, whether the establishment is inside or outside, make sure the link you pick coordinates the earth. To withstand this development, the use of flexed continuous cables with an isolated wire core is paramount. Examples of this would be when the cable is used to interface scanners, tilt cameras, and pans.

Conclusion

From the knowledge in this guide, coupled with our expertise, contact us to get the best RG59 Siamese Cable for your specific needs.